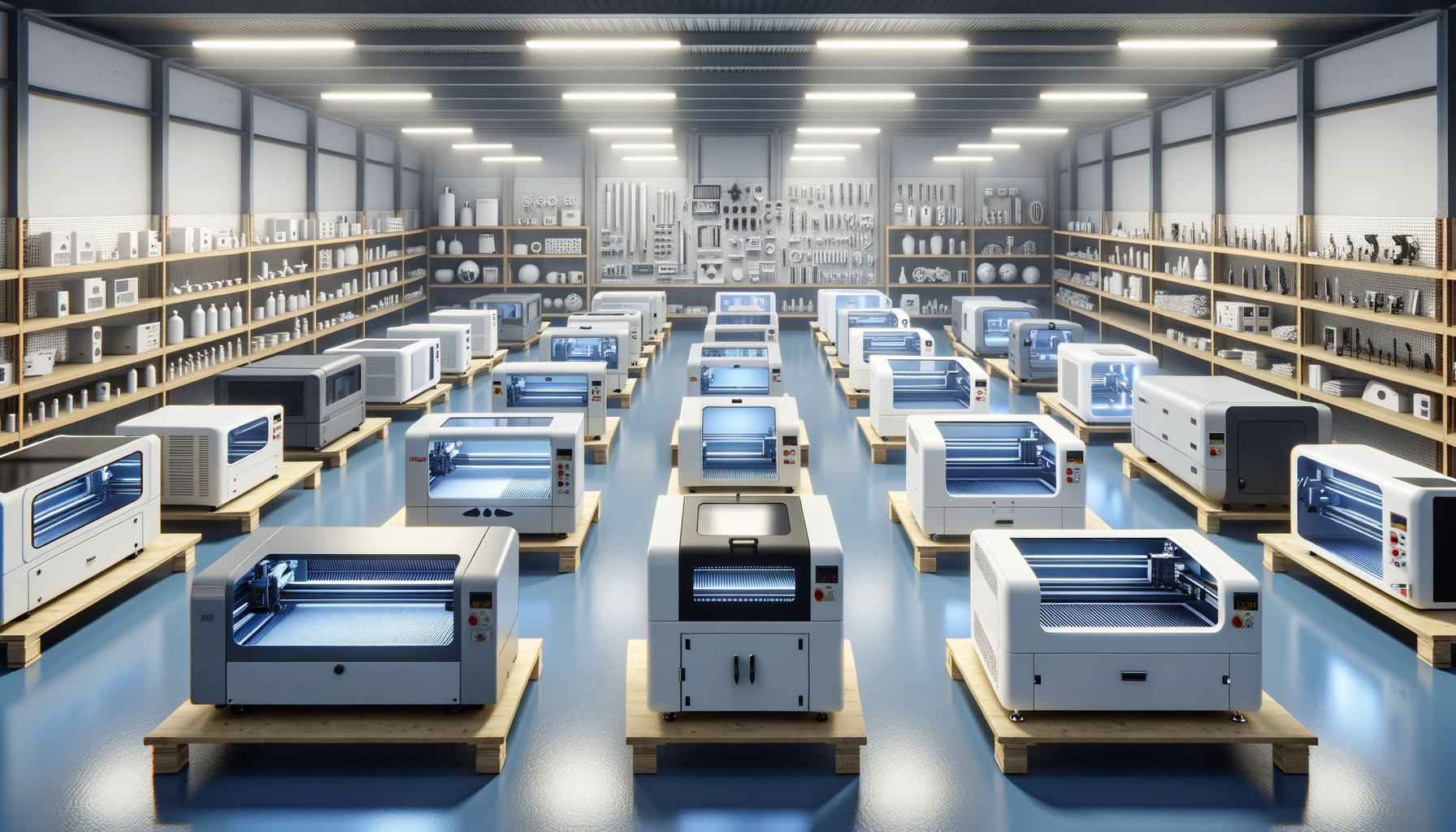

Introduction to Laser Engravers

Laser engravers have revolutionized the way we approach engraving and cutting tasks. These advanced machines utilize laser technology to precisely engrave and cut a multitude of materials, ranging from wood to metal. The versatility and precision offered by laser engravers make them an essential tool for both hobbyists and professionals. Understanding the capabilities and applications of laser engravers can help in selecting the right one for specific needs.

Understanding Laser Technology

The core of any laser engraver is its laser technology, which is responsible for the precision and efficiency of the engraving process. Lasers work by emitting a concentrated beam of light that can cut or engrave materials with high accuracy. The power and type of laser used can greatly influence the machine’s capabilities. Common types of lasers include CO2, fiber, and diode lasers, each suited for different materials and tasks.

CO2 lasers are widely used for non-metal materials like wood, acrylic, and glass due to their efficiency in cutting and engraving. Fiber lasers, on the other hand, are more suitable for metals and are known for their speed and precision. Diode lasers are often used in smaller, less powerful engravers and are ideal for light-duty tasks.

Choosing the Right Laser Engraver

Selecting the appropriate laser engraver involves considering several factors, including the material you intend to work with, the complexity of your designs, and your budget. Here are some key considerations:

- Material Compatibility: Ensure the engraver is compatible with the materials you plan to use.

- Power Requirements: Higher power lasers can cut through thicker materials more efficiently.

- Work Area Size: Consider the size of the work area if you plan to engrave larger pieces.

- Software Compatibility: Check if the engraver’s software is user-friendly and compatible with your design software.

By evaluating these aspects, you can make an informed decision that aligns with your engraving needs.

Applications and Benefits of Laser Engraving

Laser engraving is employed in a wide range of industries due to its precision and versatility. From personalizing gifts to industrial manufacturing, the applications are vast. Some common uses include:

- Jewelry Engraving: Creating intricate designs on metals and gemstones.

- Signage Production: Crafting detailed signs from wood or acrylic.

- Prototyping: Rapid creation of prototypes with precision cuts and engravings.

- Artistic Creations: Producing detailed artwork on various surfaces.

The benefits of laser engraving include reduced waste, high precision, and the ability to handle intricate designs that would be challenging with traditional methods.

Conclusion: Making an Informed Decision

Choosing the right laser engraver involves understanding both your needs and the capabilities of different machines. By considering factors like material compatibility, power, and work area, you can select an engraver that meets your requirements. Whether for personal projects or professional use, a laser engraver can enhance your ability to create detailed and precise designs. As technology continues to advance, these machines are becoming more accessible, offering a world of possibilities for creators and manufacturers alike.