Understanding Fiberglass Grating

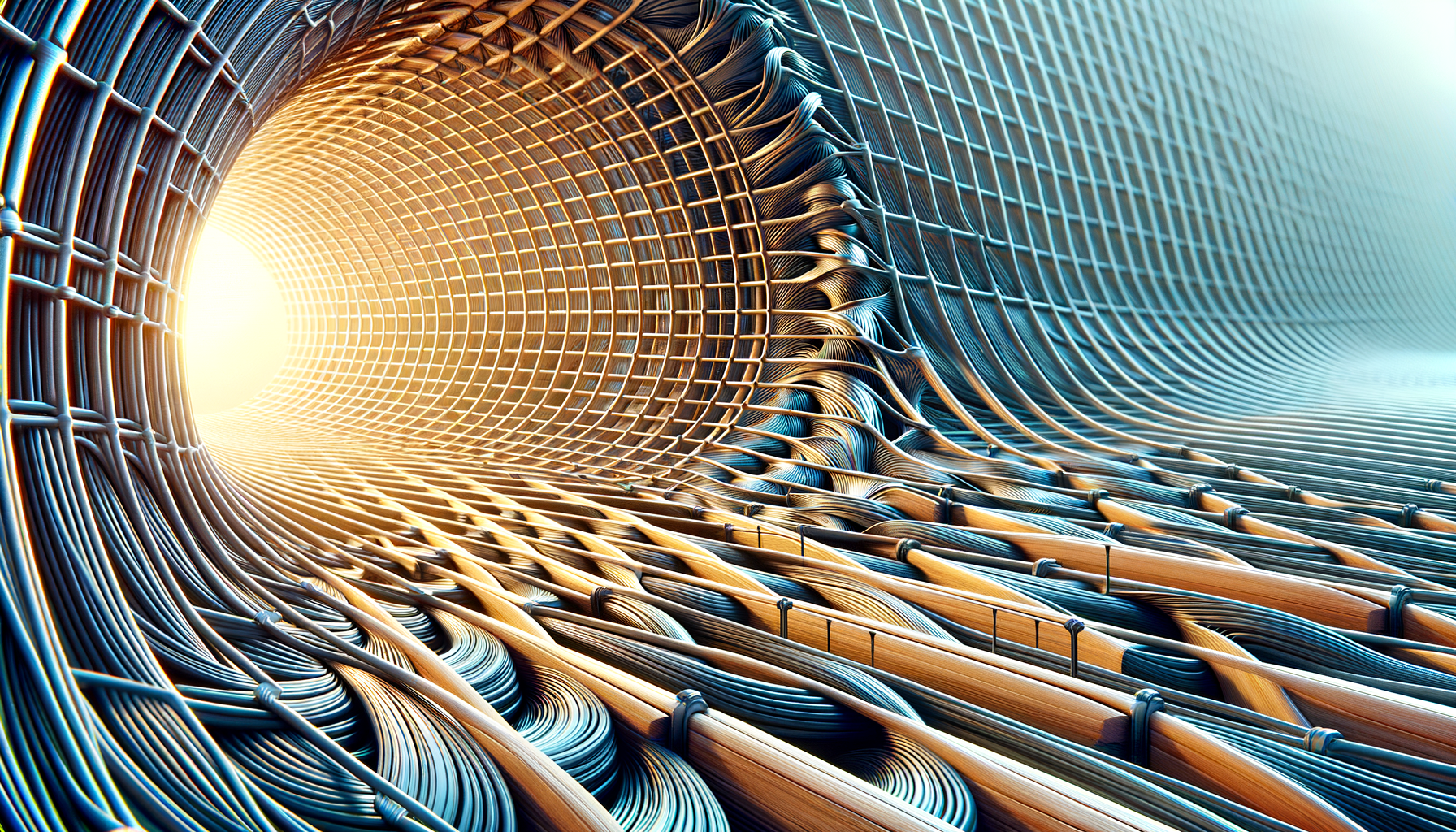

Fiberglass grating is a composite material made from fiberglass reinforced plastic (FRP), which offers a lightweight yet robust alternative to traditional materials such as steel or aluminum. This grating is commonly used in environments where corrosion resistance, strength, and low maintenance are crucial. The composition of fiberglass grating involves a matrix of resin and fiberglass strands, which are woven together to create a grid structure. This structure is then cured to form a solid, durable panel.

One of the primary reasons for the popularity of fiberglass grating is its resistance to corrosion. Unlike metal grating, fiberglass does not rust, making it ideal for use in chemical plants, water treatment facilities, and maritime environments. Additionally, fiberglass grating is non-conductive, providing a safer option in electrical applications. These characteristics make fiberglass grating a versatile option for many industries.

Furthermore, fiberglass grating is available in various types, including molded and pultruded grating. Molded grating is known for its high impact resistance and is often used in environments where durability is a priority. Pultruded grating, on the other hand, offers a higher strength-to-weight ratio, making it suitable for applications where load-bearing capacity is essential.

Applications of Fiberglass Grating

The versatility of fiberglass grating allows it to be used in a wide range of applications across different industries. One of the most common uses is in the construction of platforms and walkways. Given its lightweight and corrosion-resistant properties, fiberglass grating is ideal for creating safe and durable surfaces in industrial settings.

In the marine industry, fiberglass grating is often used for decking and dock surfaces. Its resistance to saltwater corrosion and non-slip surface make it a practical choice for these applications. Additionally, fiberglass grating is frequently used in wastewater treatment plants, where exposure to chemicals and moisture is a concern.

Fiberglass grating is also utilized in the manufacturing sector for flooring and stair treads. Its ability to withstand heavy loads and resist wear and tear makes it a reliable option for high-traffic areas. Moreover, the non-conductive nature of fiberglass grating makes it suitable for use in electrical substations and other environments where electrical safety is paramount.

Advantages of Fiberglass Grating over Traditional Materials

When comparing fiberglass grating to traditional materials like steel and aluminum, several advantages become apparent. First and foremost, fiberglass grating is significantly lighter than metal alternatives, which simplifies installation and reduces transportation costs. This lightweight nature does not compromise its strength, as fiberglass grating can support substantial loads.

Another advantage is the low maintenance requirement of fiberglass grating. Unlike metal grating, which requires regular painting or coating to prevent rust, fiberglass grating is inherently resistant to corrosion. This characteristic not only reduces maintenance costs but also extends the lifespan of the grating.

Fiberglass grating also offers excellent chemical resistance, making it suitable for use in environments where exposure to corrosive substances is likely. This resistance ensures that the grating maintains its structural integrity over time, even in harsh conditions.

Additionally, fiberglass grating provides a safer walking surface due to its non-slip properties. This feature is particularly important in wet or oily environments where slip hazards are a concern. The non-conductive nature of fiberglass grating also enhances safety by reducing the risk of electrical shocks.

Installation and Maintenance of Fiberglass Grating

Installing fiberglass grating is a straightforward process, primarily due to its lightweight nature. The panels can be easily cut to size using standard tools, allowing for customization to fit specific applications. The grating is typically installed using clips or fasteners, which secure it in place and ensure stability.

One of the key benefits of fiberglass grating is its low maintenance requirement. Unlike metal grating that may require frequent painting or coating to prevent rust, fiberglass grating remains unaffected by corrosion. This property significantly reduces the need for ongoing maintenance and associated costs.

To maintain the appearance and functionality of fiberglass grating, regular cleaning is recommended. This can be accomplished using a mild detergent and water to remove dirt and debris. In cases where the grating is exposed to chemicals, it is important to follow the manufacturer’s guidelines for cleaning to ensure the longevity of the material.

Overall, the ease of installation and minimal maintenance make fiberglass grating an attractive option for industries seeking durable and cost-effective solutions for their flooring and platform needs.

Environmental Impact and Sustainability of Fiberglass Grating

In today’s world, sustainability is a key consideration in the selection of building materials. Fiberglass grating offers several environmental benefits, making it a responsible choice for eco-conscious industries. One of the primary advantages is its long lifespan, which reduces the need for frequent replacements and minimizes waste.

The production of fiberglass grating involves fewer emissions compared to traditional metal grating, contributing to a lower carbon footprint. Additionally, the lightweight nature of fiberglass grating reduces transportation energy consumption, further enhancing its environmental credentials.

Fiberglass grating is also resistant to rot and decay, eliminating the need for chemical treatments that can be harmful to the environment. This resistance ensures that the grating remains in service for extended periods without the need for environmentally damaging maintenance practices.

Furthermore, many manufacturers are now producing fiberglass grating using recycled materials, enhancing its sustainability profile. By choosing fiberglass grating, industries can contribute to a more sustainable future while benefiting from a material that offers exceptional performance and durability.